If you own an integrale then you have in your possession a piece of complex automotive history, please treat it with the respect it deserves!

So many cars come through those workshop doors in such shoddy condition it is a crying shame, bits missing, parts put on back to front, oil leaking out of every silicone bodged orifice. Quite often the cost of the work involved to bring these cars back to a roadworthy condition is more than the car is worth and it is so sad that much of my job is spent finishing someone elses job off because they got so far in and realised they were out of their depth or just made such a hash of things that they caused more damage than than they did good.

If you can't afford to look after an integrale then don't buy one and they are expensive cars to run.

Think with your head and not your pocket.

I sometimes get asked to fit other peoples supplied products, the answer is usually 'No thanks':

1. When you go out for a meal do you take your own food with you and ask them to cook it? How do you think we stay in business?

2. If the car later develops a fault which could be linked with or solely blamed of this part where does the fault lie? The part? the fitting? Then the arguments start....

There are a few well respected integrale Specialists dotted around the country, please use and support them as they charge what they do because they have the parts and the knowledge to keep your car in top condition. In these times of ever declining spare parts, knowledge and common sense believe me, it ain't no easy task.

Thursday 31 December 2009

Sunday 27 December 2009

Centre Lathe

When I first started earning a crust at the age of 16 I was trained to use machines, both in the workshop and at college, I've always enjoyed working with them and still have all my own fingers...

Back in Summer I decided it was time we invested in a centre lathe, there were a few reasons for this.

The integrale is of course not a new car anymore and so many come in with bits and pieces missing, on a new engine build this was never going to do was it:

?

With many parts NLA or taking a long time to get hold of you have to take matters into your own hands in order to survive and get the job done:

The same car came in with one of the map sensor nipples snapped off and someone had tried glueing it back on, but the glue had run into the sensor and blocked the hole so when plugged into the scanner there was no reading. The car was needed and map sensors are expensive so the solution was quick, easy and permanent:

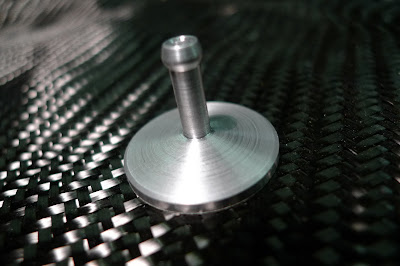

A clutch centering tool was also one of the first things I made after not really getting on with the universal ones you can buy:

To be able to make your own precision parts as and when you need them without having the problems involved with sub contracting them out is very satisfying, the lathe is a such a versatile tool it's difficult to imagine work life without it..

Some other bits:

Cheating a bit here, but it did the job:

Cheating a bit here, but it did the job:I don't think we'll be winning any awards, but it gets the job done and properly.

Saturday 26 December 2009

Auxiliary belt tensioners

At last a replacement for those badly specced cast iron things which snap so easily...

Made from Zinc plated billet steel these won't ever break!

Click on the banner at the top of the Blog to gain access to the site for prices.

Track of the month: http://www.youtube.com/watch?v=steC-8NSVIw

Poignant lyrics.

Made from Zinc plated billet steel these won't ever break!

Click on the banner at the top of the Blog to gain access to the site for prices.

Track of the month: http://www.youtube.com/watch?v=steC-8NSVIw

Poignant lyrics.

Project Evo Chapter one.

A bit of a slow burner this one, I'm hoping to get it finished before we stop using petrol to power cars as I have some radical new parts to use on it.

The idea behind it is simple, It will be a no compromise track car, be as light, powerful and handle as well as possible.

I started off with a straight, but rather rusty shell. It was cheap enough and I figured by the time I had hacked it about to strengthen it, lighten it, make things fit better and added light weight panels it would have been sacrilegious to start with a decent one, they've all got rust on them anyhow!

Sandblasting in progress:

The neighbours were well impressed.

It came out nice and clean though with an excellent surface for the primer to cling to. I masked off the seams so they could be welded afterwards:

The rusty sunroof equipped roof panel has been taken off and we made a carbon fibre replacement, lots lighter and also stronger, it will eventually be equipped with all the composite panels we do.

As you can see in the pics above I started on it at home, just doing a bit on free weekends. I bought some A frames and turned them into a spit so I could spin the shell around to gain access to every part, if you are working comfortably and safely you are going to spend more time getting the job done just right. The spit is now at the workshop for use on customer cars.

I handmade all the strengthening plates to the front end:

I knew that Metalworking course at college would come in handy one day!

Right now it is having the cage fitted and welded in, seam welding and the strengthening plates welding on. Every item was degreased and etch primed before being welded. Etch primer is the one and only thing which you should use on bare metal, it won't scratch off very easily at all as it attaches itself chemically to the metal. It's also good near the welded areas as it doesn't come loose, burn and flake off, it just goes orange.

The engine bay was braced and the suspension arms bolted on to prevent any possibility of warpage from the welding.

Favourite track last month but one(!) http://www.youtube.com/watch?v=lLJf9qJHR3E

Not usually a fan of folk, but this hits the spot. Just 4 guys and some basic instruments, make the most of it 'cos the follow up is rubbish.

The idea behind it is simple, It will be a no compromise track car, be as light, powerful and handle as well as possible.

I started off with a straight, but rather rusty shell. It was cheap enough and I figured by the time I had hacked it about to strengthen it, lighten it, make things fit better and added light weight panels it would have been sacrilegious to start with a decent one, they've all got rust on them anyhow!

Sandblasting in progress:

The neighbours were well impressed.

It came out nice and clean though with an excellent surface for the primer to cling to. I masked off the seams so they could be welded afterwards:

The rusty sunroof equipped roof panel has been taken off and we made a carbon fibre replacement, lots lighter and also stronger, it will eventually be equipped with all the composite panels we do.

As you can see in the pics above I started on it at home, just doing a bit on free weekends. I bought some A frames and turned them into a spit so I could spin the shell around to gain access to every part, if you are working comfortably and safely you are going to spend more time getting the job done just right. The spit is now at the workshop for use on customer cars.

I handmade all the strengthening plates to the front end:

I knew that Metalworking course at college would come in handy one day!

Right now it is having the cage fitted and welded in, seam welding and the strengthening plates welding on. Every item was degreased and etch primed before being welded. Etch primer is the one and only thing which you should use on bare metal, it won't scratch off very easily at all as it attaches itself chemically to the metal. It's also good near the welded areas as it doesn't come loose, burn and flake off, it just goes orange.

The engine bay was braced and the suspension arms bolted on to prevent any possibility of warpage from the welding.

Favourite track last month but one(!) http://www.youtube.com/watch?v=lLJf9qJHR3E

Not usually a fan of folk, but this hits the spot. Just 4 guys and some basic instruments, make the most of it 'cos the follow up is rubbish.

Subscribe to:

Posts (Atom)

Search This Blog

Blog Archive

About Me

- Martin

- Welcome to the Deltaparts Blog, here you will find, well, anything which is on my mind I guess, but mainly things to do with the Lancia Delta integrale and in particular anything to do with my business, Deltaparts. It will be a bit irregular as it's not every day (or even week) that something worth mentioning happens. I would like to try and make it interesting - at least to some people anyhow, but also hopefully accessible and readable for the average 'man on the street' so I won't bore you with loads of large words, bombastic overblown sentences or technical jargon. I will describe on here how lots of the parts that we sell came about as there isn't room on the website ( www.deltaparts.co.uk ) to explain. I hope you enjoy reading it as I do writing it, when something becomes a chore you know it's time to stop doing it....